The Results: First Impressions

The order was submitted on the evening of February 15; it arrived here February 24. That’s 9 days (since it was submitted in the evening), but when you account for the weekend in the middle, their lead time estimate was accurate. Five business days to make ’em, and two to ship ’em here. Not ideal, but not too bad – and I’m not paying for rush service.

My only issue with this is the price I paid for shipping: $17.85 for UPS Ground from Aurora, CO to the Los Angeles area. This is really a general rant; it isn’t the fault of Advanced Circuits. Shipping rates have risen across the board, and it’s getting ridiculous to the point that I’m starting to ship via the USPS again in many cases. It’s a lot cheaper!

If you read my previous post, you know that in addition to my boards, they shipped me some microwave popcorn; not sure why, really. I don’t even like the stuff!

Visually, everything seems good on initial inspection. The boards are no different from what ExpressPCB would have supplied. Of course, that doesn’t mean much; usually if a board has problems, they’re going to be pretty well hidden, right up until it kills your circuit.

And so we take a closer look.

Through The Looking Glass

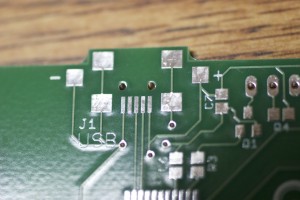

The first thing I was curious about was whether there was solder mask (“web”) between the pads for the USB connector and the processor. Granted, this is only supposed to be a problem on much finer-pitch components, but it’s still important. Everything looked okay there, as evidenced by the USB connector footprint, shown on the left.

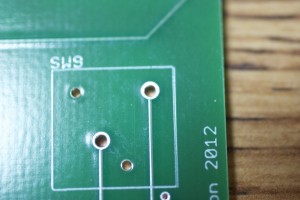

Another major issue is the accuracy of drill hits. You’ve probably seen the various images over at SparkFun of bad boards they’ve gotten, where the drill was misaligned with a given pad or via; it gets ugly, apparently. For this order, the accuracy seems to be pretty good, though; there are a couple of very minor examples of drill hits that aren’t perfectly centered, but not nearly enough to matter.

The reality is, I should have bumped the size up on the pads in question anyway; they’re way too small (those aren’t supposed to be vias!). The copper area around the hole is called the “annular ring”; most board houses usually have a metric that tells you just how thin you can make your annular ring before you run into problems.

I didn’t run into problems, but any smaller and I very well may have.

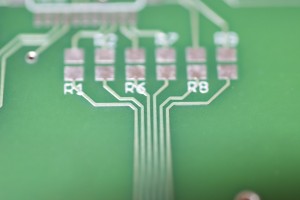

As far as resolution goes, the results are excellent, near as I can tell. My 8mil spaces are very well defined, and the traces themselves are all nice and solid. It really didn’t take much examination to determine this, and it’s not that surprising; 8mil isn’t all that small given what people are doing with high density boards these days.

A basic electrical check reveals that all the traces reach where they’re supposed to, which is good. I’ve never actually had a board fail that test, though I’ve heard some horror stories. It’s still worth testing, though, rather than waste a lot of expensive parts on a bum board.

As far as the finish goes, everything looks good there, too (though it doesn’t show up all that well in pictures). All the exposed copper pads are coated with a nice layer of lead-free solder, and it seems to be completely level, at least as far as the naked eye can see.

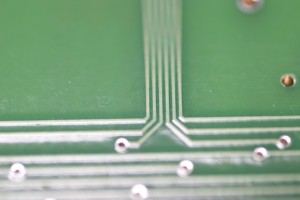

In fact, the only minor gripe I can point to is with the solder mask, and it may be my imagination; you be the judge. If you click the image at right, you can see a slight discoloration over the traces, almost as though the copper is peeking through (and yes, this is visible with the naked eye, not just with a macro lens!). It doesn’t appear to be a functional issue (the traces are still covered by a dielectric layer), but it would appear to me that the solder mask is just a hair too thin.

For now, though, it boils down to an aesthetic issue, and it wouldn’t surprise me in the slightest to find out that all boards are like this to some degree. Feel free to leave a comment if you know differently, or perhaps have another explanation for the inconsistency.

I only wish I’d stuck a few polygon pours on the board with nearby traces and whatnot. Would’ve been useful to see the results, but I didn’t think of it at the time.

Final Assessment

In spite of the initial foible with customer service, I’m very satisfied with the service I received from Advanced Circuits. Subjectively, the boards feel slightly higher quality than what ExpressPCB provides, and the service was reasonably prompt. The only thing I could really ask for (besides costing less) would be a slightly faster turnaround time; ExpressPCB has them beat on that score.

Oh, and you’ll want to watch out for the order number they add to the bottom silkscreen layer. I don’t think that’s avoidable with them.

The only major downside is one you’ll find with just about any board house out there: the cost. While the boards themselves are only $33 each, they stick you with a minimum order of four boards, which means you’re going to be paying around $150 including shipping. If I could place a $50 order with them for one or two boards, I’d be a much happier camper, and use their service much more frequently than I expect I’ll be doing.

Perhaps I’ll review BatchPCB next time I need to have a board made; while the lead times are quite a bit longer, the price is much more in line with what I’d like to be paying since I can order only one or two boards.

S.

Next up: the TuneConsole build (or: my harrowing experiences with surface mount madness!)

If you’re still interested in different PCB fab options, I’d highly suggest the group service provided at DorkbotPDX (http://www.dorkbotpdx.org/wiki/pcb_order). I’ve ordered from them and enjoyed the prices and the board I got. I’ve placed another order with them recently, and the person putting together the order was very helpful when I made some stupid mistakes.

I used Advanced Circuits for several boards which I made in college a few years ago, and I did very much like their software and not worrying about paying by the inch. But since I left school and started using KiCad and DorkbotPDX, I haven’t been at all disappointed. I tried going back to Advanced Circuits’s software a few months ago, and it just didn’t seem to work for me as well once I’d been creating with KiCad for awhile. If you’re still interested in considering other suppliers, I’d highly suggest these two.

By the way, awesome job on the iTunes rating system!

Pingback: An iTunes rating box for everyone - Hack a Day